Despite common misconceptions, plastic is one of humanity’s greatest material innovations. It is strong, lightweight, hygienic, and essential to modern life — from lifesaving medical equipment to food preservation and global logistics. Plastic itself is not the enemy.

The real challenge is what happens after plastic becomes waste. When mismanaged, it ends up in landfills, the open environment, rivers, and oceans, where it slowly breaks down into harmful microplastics. These microplastics contaminate the water we drink, the food we eat, the soil we grow on, and even the air we breathe. The solution is not to ban plastic, but to manage plastic waste responsibly and circularly.

Corsair provides a practical, scalable solution. Through our advanced pyrolysis technology, we turn plastic waste back into valuable pyrolysis oil, a certified raw material used by petrochemical companies to create new, more environmentally responsible plastic products. This closes the loop, giving waste plastic a new life while helping to protect the planet.

7

4

100+

14

06

40+

20M+

20M+

Corsair uses pyrolysis to turn plastic waste into a valuable product called pyrolysis oil. In this process, plastic is heated to very high temperatures without any oxygen, so it doesn’t burn. Instead, it breaks down into three main parts: pyrolysis oil, gas, and solid residue (char).

Corsair uses pyrolysis to turn plastic waste into a valuable product called pyrolysis oil. In this process, plastic is heated to very high temperatures without any oxygen, so it doesn’t burn. Instead, it breaks down into three main parts: pyrolysis oil, gas, and solid residue (char).

Corsair uses pyrolysis to turn plastic waste into a valuable product called pyrolysis oil. In this process, plastic is heated to very high temperatures without any oxygen, so it doesn’t burn. Instead, it breaks down into three main parts: pyrolysis oil, gas, and solid residue (char).

Corsair uses pyrolysis to turn plastic waste into a valuable product called pyrolysis oil. In this process, plastic is heated to very high temperatures without any oxygen, so it doesn’t burn. Instead, it breaks down into three main parts: pyrolysis oil, gas, and solid residue (char).

Corsair transforms discarded plastic waste into a high-value oil product through advanced pyrolysis, a next-generation chemical recycling technology. During pyrolysis, plastic waste is heated in an oxygen-free environment, allowing the material to break down into liquid at the molecular level.

This controlled process produces three key outputs:

Pyrolysis Oil – a high-quality liquid that can be used by major petrochemical companies to create the building blocks for new, more sustainable plastics, helping to close the loop in the circular economy.

Gas – an energy-rich gas that is captured and reused by the pyrolysis units to generate the heat needed for the process, significantly improving overall energy efficiency.

Solid Residue (Char) – small amounts of carbon black -type of material that can be utilized by a variety of industries.

Corsair’s operating model, modular facility design, and strict quality control allow us to consistently produce ISCC-certified pyrolysis oil that meets the demanding feedstock specifications of global industry leaders. This operating process is deployed across Corsair’s expanding network of facilities worldwide, positioning the company as one of the fastest-growing leaders in the global plastic waste recycling sector.

Pyrolysis oil is an in-demand, premium-grade material used by global petrochemical companies to manufacture the building blocks for new, more environmentally responsible plastics. When upgraded through refinery and steam-cracking processes, this oil becomes the base for producing certified circular polymers used in everyday products such as:

At Corsair, quality is not merely a goal—it is the core principle guiding every part of our operation. As one of the fastest-growing companies in the plastic-waste chemical recycling industry, we understand that producing a consistent, globally recognized, and high-value product requires unwavering standards from start to finish. Every step—from plastic waste collection to processing, certification, and delivery—is governed by systems designed to ensure precision, safety, and transparency.

Our facilities operate using advanced modular designs, automated control systems, and strict operational protocols that guarantee repeatable performance and uniform output across all global locations. Each shipment of pyrolysis oil from Corsair undergoes comprehensive laboratory analysis to confirm it meets the demanding specifications required by leading petrochemical companies.

Quality at Corsair extends beyond the oil we produce—it begins at the very source of our material. All plastic waste collected under Corsair’s ecosystem follows the CPRS – Corsair Plastic Waste Removal Standard, a third-party audited framework that ensures every kilogram of plastic is genuinely removed from the environment in a measurable, traceable, and verifiable way. This standard underpins the integrity of our entire circular model, guaranteeing that the raw material entering our facilities is ethically sourced and environmentally impactful.

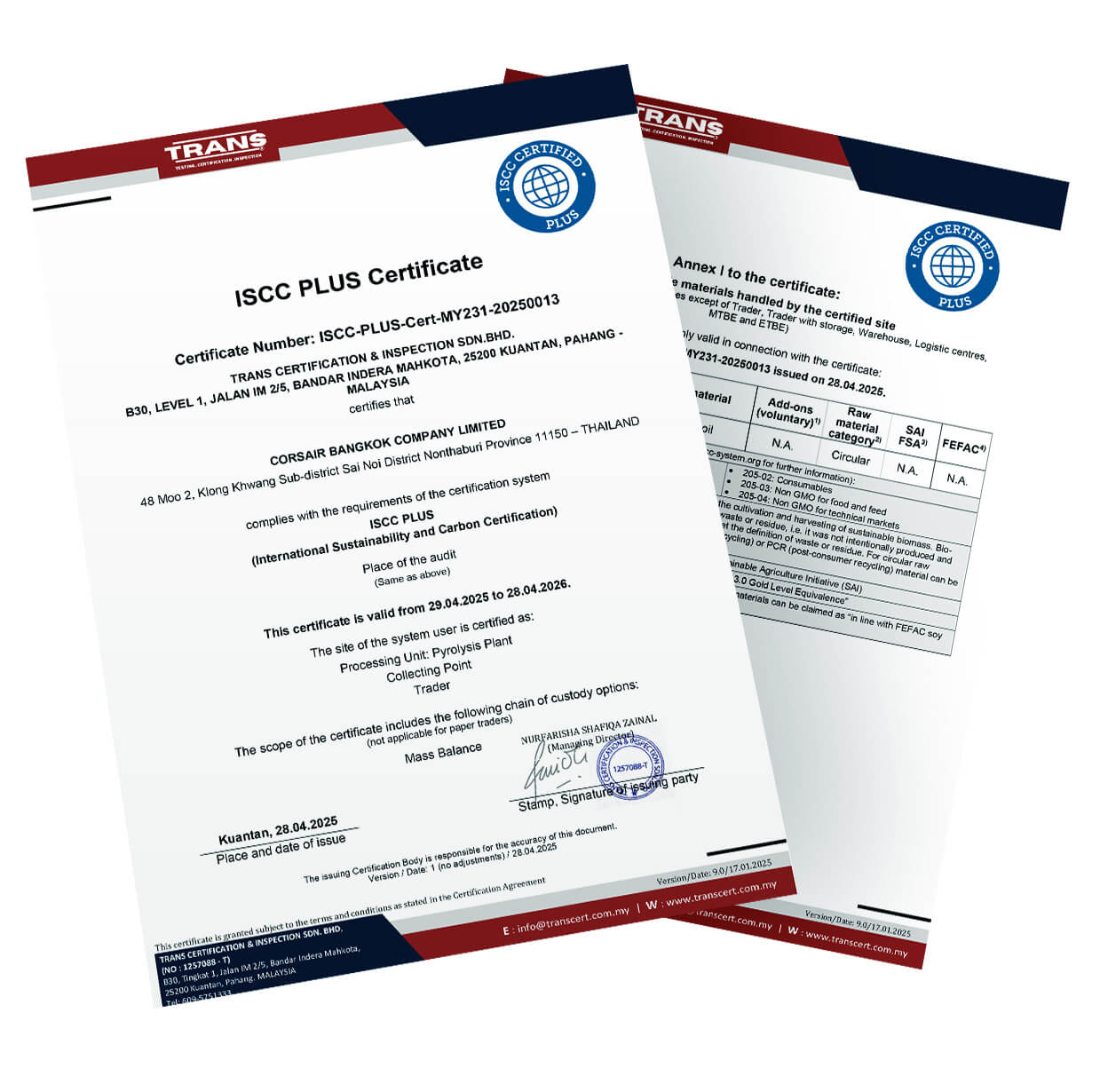

In addition, Corsair’s production processes comply with internationally recognized certification frameworks such as ISCC (International Sustainability and Carbon Certification), ensuring full traceability, sustainable operations, and alignment with the highest circular-economy requirements. These certifications enable Corsair’s pyrolysis oil to be accepted by major global petrochemical companies seeking reliable, circular feedstocks.

By uniting advanced technology, rigorous quality procedures, and transparent environmental standards like CPRS and ISCC, Corsair delivers a product and a system that meet or exceed the expectations of the world’s most demanding industrial partners. This commitment to excellence is what positions Corsair at the forefront of the global transition to truly circular plastic production.

The global demand for circular, sustainable raw materials has never been stronger—and it is accelerating at an unprecedented pace. As governments, corporations, and consumers intensify their focus on environmental responsibility, the pressure on industries to reduce their reliance on virgin resources and increase recycled content has become a defining force in the market.

Major petrochemical companies, packaging producers, consumer brands, and industrial manufacturers are now committing to ambitious sustainability goals that require vast quantities of certified recycled feedstock. Pyrolysis oil—especially ISCC-certified, high-quality pyrolysis oil like the kind produced by Corsair—has emerged as one of the most critical materials needed to meet these targets.

This surge in demand is driven by multiple global trends:

Expanding regulatory requirements in the European Union, North America, and Asia mandating minimum levels of recycled content in plastic products.

Corporate sustainability commitments, with many Fortune 500 companies pledging to use only recycled or renewable plastics by 2030 or earlier.

Growing consumer expectations for environmentally responsible packaging and materials.

The urgent need to reduce plastic pollution, requiring scalable, industrial-grade recycling solutions.

As plastic production is projected to triple by 2050, the world is facing a critical shortage of circular feedstock. Mechanical recycling alone cannot meet the volume or quality requirements of modern industries, creating an enormous opportunity for advanced chemical recycling technologies.

Corsair is uniquely positioned to meet this rising demand. Our expanding network of facilities across the globe, combined with our strict quality-control systems, ISCC certification, and CPRS-backed waste collection, enables us to supply the global petrochemical industry with reliable, traceable, circular raw materials at scale.

This rapidly growing demand is not a temporary trend—it is a structural shift shaping the future of plastics. Corsair stands at the forefront of this transformation, delivering the materials industry needs to achieve a truly sustainable and circular world.

This certification confirms that Corsair operates under rigorous international sustainability standards, enhances its credibility in the industry.

It reinforces our commitment to promoting the circular economy and the global transition toward more responsible production practices.

This certification confirms that Corsair operates under rigorous international sustainability standards, enhances its credibility in the industry.

It reinforces our commitment to promoting the circular economy and the global transition toward more responsible production practices.

Our offtake partner for the output from our Kaipola facility in Finland, plus future European sites. Pyrolysis oil from Kaipola is delivered to Shell’s facility in Moerdijk, The Netherlands for the production of circular new plastics.

Our offtake partner for the output from our Kaipola facility in Finland, plus future European sites. Pyrolysis oil from Kaipola is delivered to Shell’s facility in Moerdijk, The Netherlands for the production of circular new plastics.

Energy and infrastructure solutions for Singapore and Asia Pacific. Aster is committed to enabling a responsible energy future and becoming the partner of choice for sustainable industry transformation.

Shell Chemicals Europe B.V. is one of our

main offtake partners for the output from

Corsair’s Kaipola facility in Finland, as well

as designated future European production

sites. This partnership represents a major

milestone in Corsair’s mission to supply

high-quality, ISCC-certified circular

feedstock to the world’s leading

petrochemical companies.

Pyrolysis oil produced at Kaipola is to be

transported to Shell’s state-of-the-art

facility in Moerdijk, The Netherlands, where

it is utilized as a raw material in the

production of the building blocks for new,

circular plastics. By integrating Corsair’s

recycled feedstock into their operations,

Shell advances its global strategy of

increasing the use of certified circular

materials across its value chain.

Working with Shell not only validates the

quality and consistency of Corsair’s

pyrolysis oil, but also positions Corsair as a

key contributor to Europe’s rapidly

expanding circular-plastics ecosystem.

The collaboration serves as a strong

foundation for scaling future facilities and

supporting the continent’s transition

toward a more sustainable, lower-carbon

materials economy.

Aster is one of Corsair’s primary offtake

partners for pyrolysis oil produced across

our Asian facilities. As a leading provider of

energy and infrastructure solutions for the

wider Asia-Pacific region, Aster plays a

pivotal role in advancing sustainable

industry transformation throughout one of

the world’s fastest-growing markets.

Aster is committed to enabling a

responsible energy future, and its

collaboration with Corsair supports this

mission by integrating ISCC-certified

pyrolysis oil into regional supply chains as a

circular alternative to traditional virgin

fossil feedstock. Through this collaboration,

Corsair’s high-quality recycled pyrolysis oil

becomes part of the materials pipeline

used to create new circular plastics and

low-carbon products for a wide range of

industries.

The Asia-Pacific region is a global center

for manufacturing, logistics, and

petrochemical processing—making the

demand for circular raw materials

exceptionally strong. Aster’s wellestablished network, deep regional

expertise, and long-term commitment to

sustainability make them an ideal partner

for supporting Corsair’s growth across Asia,

including Thailand, Sri Lanka, and future

operational sites.

By working together, Corsair and Aster are

helping to accelerate the shift toward a

more circular and environmentally

responsible plastics economy in Asia,

strengthening supply chains and creating

long-term value for both industry and the

planet.

Kera Energy is one of Corsair’s principal

offtake partners for pyrolysis oil produced

at our Kaipola facility in Finland, with the

collaboration set to expand as Corsair

commissions additional facilities across the

globe.

By integrating Corsair’s ISCC-certified

pyrolysis oil into their operations, Kera

Energy supports the global transition away

from virgin fossil-based inputs and helps

major brands meet increasingly strict

regulatory requirements for recycled

content.

Kera Energy is recognized for its

commitment to innovation, sustainability,

and the development of next-generation

circular materials.

The collaboration between Corsair and

Kera Energy strengthens the global

circular-plastics supply chain, reduces

environmental impact, and ensures that

recycled materials can be produced at

scale with consistent, reliable quality.

As Corsair continues to expand its

footprint internationally, Kera Energy is

positioned to operate as a key strategic

partner in delivering certified circular raw

materials to some of the most demanding

industries in the world.